Airbus Protect has been analyzing and controlling risks for more than 35 years, with the aim of securing the mobility of the future, protecting people, infrastructures and economic interests. Numerous studies related to fire risk have been carried out, positioning Airbus Protect as a key player in infrastructures such as ICPE (classified installation for environmental protection) and INB (basic nuclear installation).

The fire resistance study consists of evaluating the performance of a load-bearing structure in a fire situation. In other words, it allows the evaluation of the time during which the structure continues to ensure its role (criterion R of mechanical resistance) when it is heated by the effects of a fire.

This study is based on a preliminary analysis of the fire risk and on the constructive provisions, in particular the civil engineering plans of the building. Generally, this requires the use of both ISO 834 fire (representative of a generalized fire for “common” operation premises – see below) and real fire for premises with particular operation and/or configuration (presence of hydrocarbons, localized fire heating the metal structure elements in a non-uniform way, etc.).

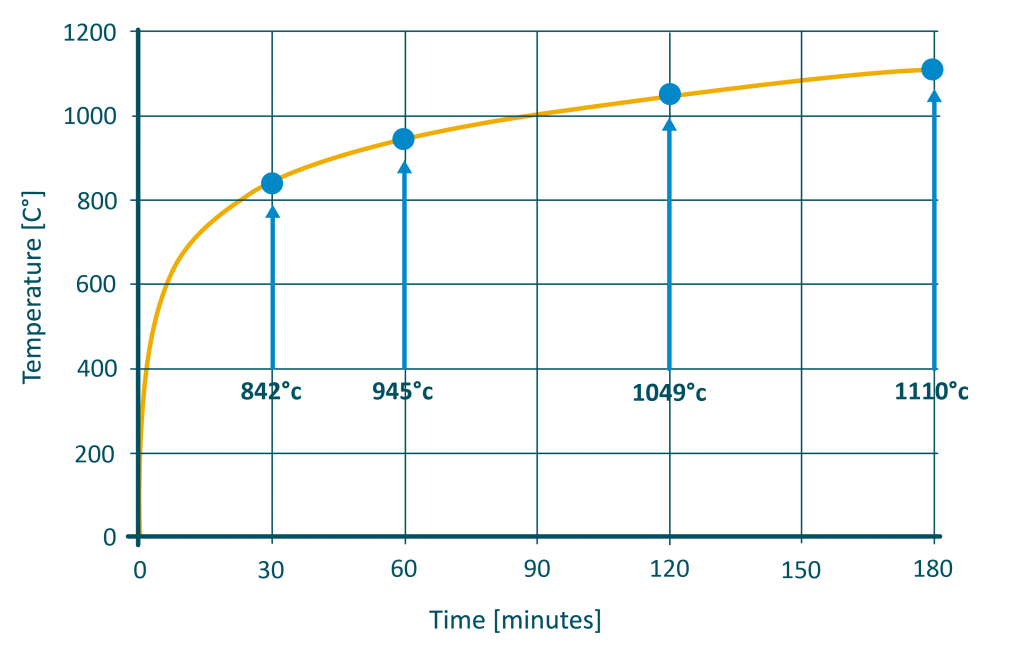

The ISO 834 fire, also called “conventional fire”, is used to dimension the fire resistance degree required for different types of structures (housing, offices, establishments receiving the public, etc.). A concrete example? If you live in a single-family house, the required fire resistance degree for vertical load-bearing elements (walls, for example) is 15 minutes. This is the same “ISO fire” that is used to qualify the famous fire doors that are part of our daily lives in the office or in supermarkets. Conventional fire represents a temperature rise that reaches more than 840°C at 30 minutes and exceeds 1000°C at 2 hours.

Sustainability

Sustainability